The World's Most Advanced Vulcanization Technology: HTR and UBR Systems

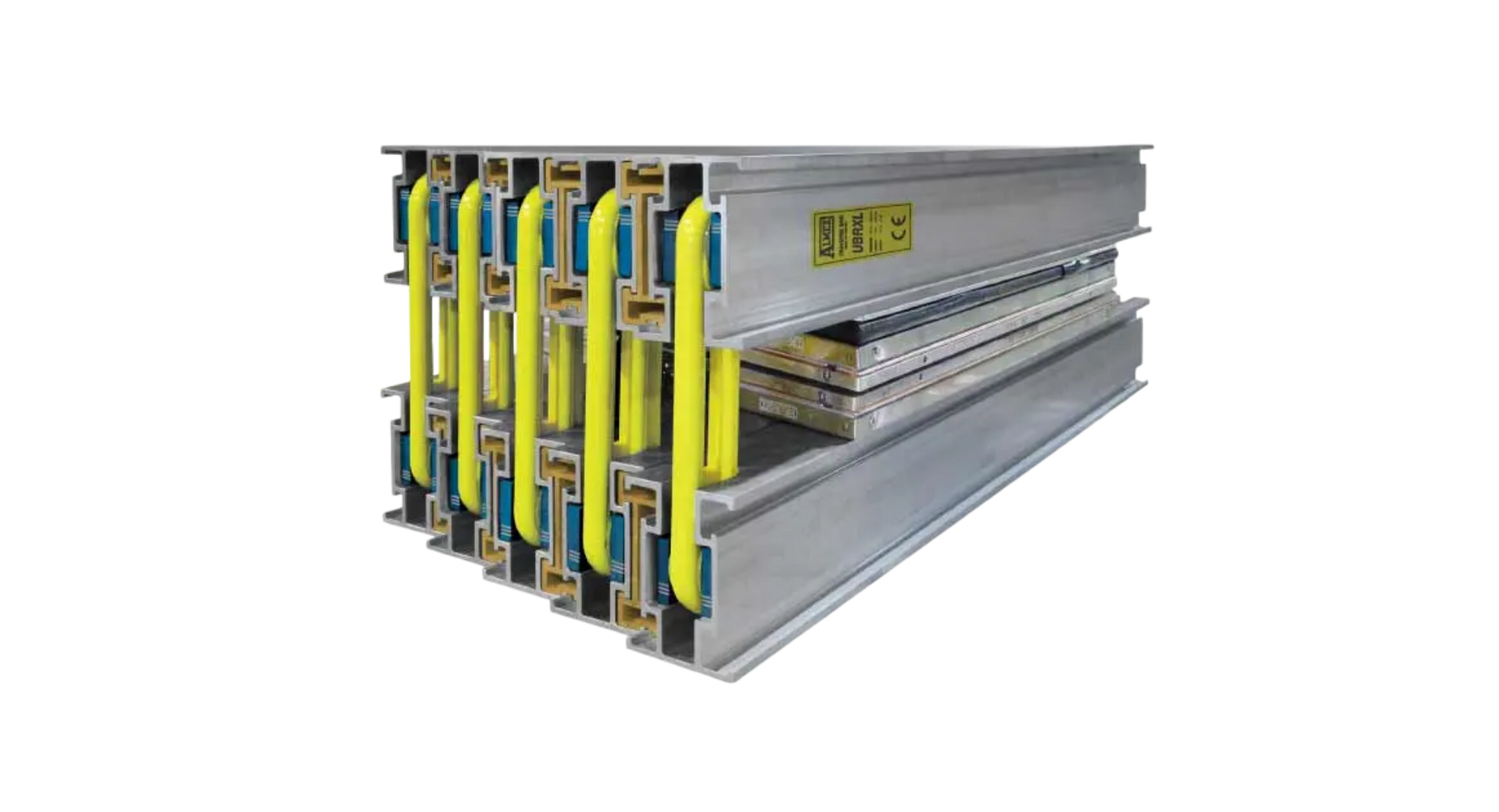

The UBR press combines ultra-light extruded-aluminium bars (just 13.5 kg / m) with HTR high-tensile composite clamps, replacing heavy bolted beams in conventional presses. Three bar profiles—UBR (yellow), UBRX (red) and UBRXL (blue)—match any splice length and pressure demand, delivering a uniform 100 psi (7 bar) standard pressure or 200 psi (14 bar) with an optional high-pressure pump. Fast-heat silicone platens reach 160 °C in about 15 minutes and cool below 60 °C in roughly 10 minutes via built-in water channels. Designed for both textile and steel-cord belts, the modular UBR system is field-portable, installs with minimal manpower and keeps mining, cement and power-generation conveyors running with durable, on-site repairs.

HTR clamps lock the lightweight bars in place, eliminating heavy pressure bolts. The result is faster set-up, lower lifting loads and consistent bar spacing for safe, reliable curing.

Three: UBR, UBRX and UBRXL. Larger profiles handle higher splice pressures; the correct bar is selected to suit belt width, splice length and desired curing pressure.

Each bar weighs only 13.5 kg per metre, and HTR clamps are up to 70 % lighter than traditional pressure bolts—making the entire press easy to carry and assemble by a small crew.

Silicone heating elements reach cure temperature (160 °C) in ~15 minutes; integrated water channels cool the press below 60 °C in ~10 minutes, slashing total downtime.

Standard pneumatic operation delivers 100 psi (7 bar). Pairing the press with HP25Max or HPP20-4 hydraulic pumps raises pressure to 200 psi (14 bar) for steel-cord splices.

Compatible with T6, SG1 and ground-fault-protected T4-GF panels. RC3 and RC3P-Log models add dual digital temperature control and USB data logging.